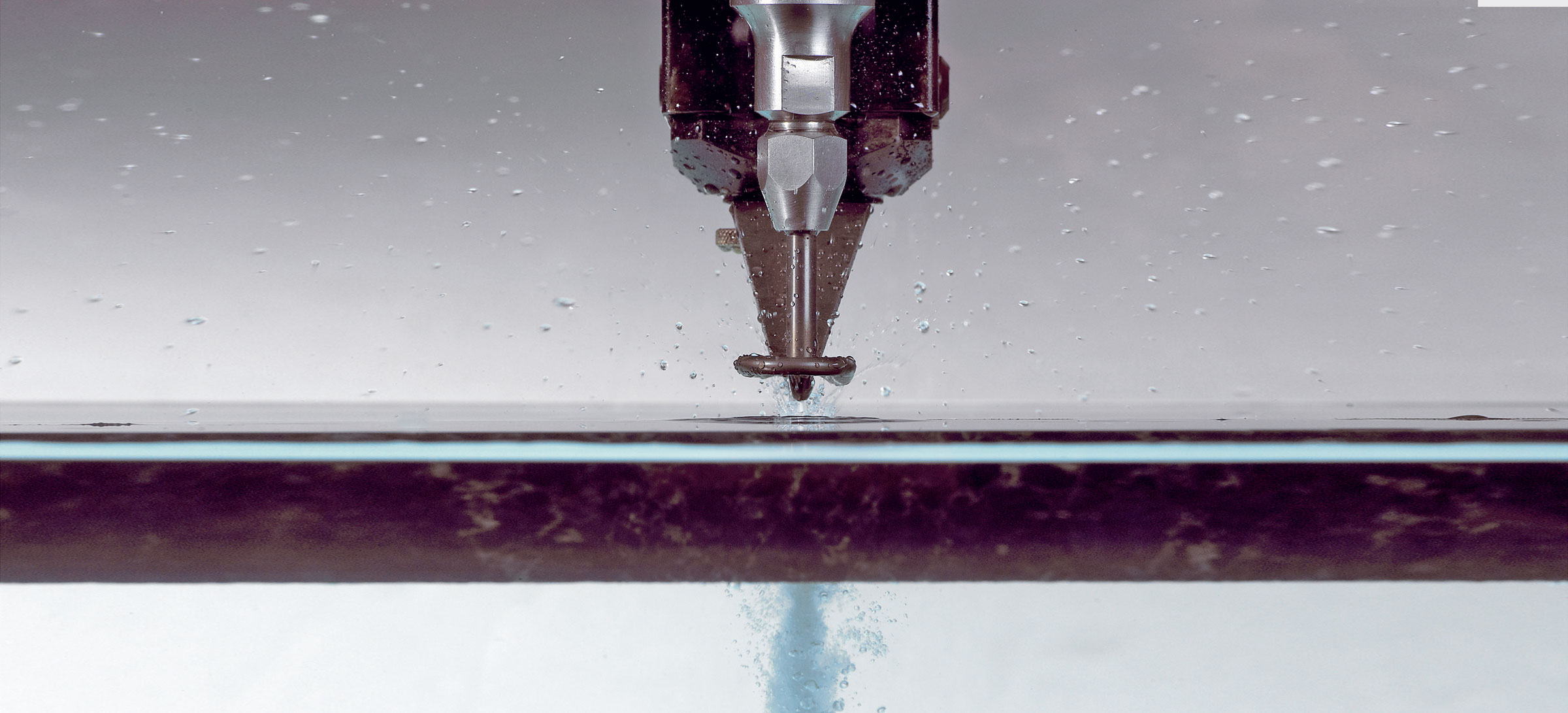

Cut a variety of materials Waterjets can cut a wide variety of materials including, metal, wood, stone, glass, composites, ceramic and acrylics. No heat affected zone Waterjet cutting does not create heat during the cutting process, so there is no heat-affected zone or thermal distortion which occur with lasers. Waterjets have a low environmental impact… Read more »

Recent Comments