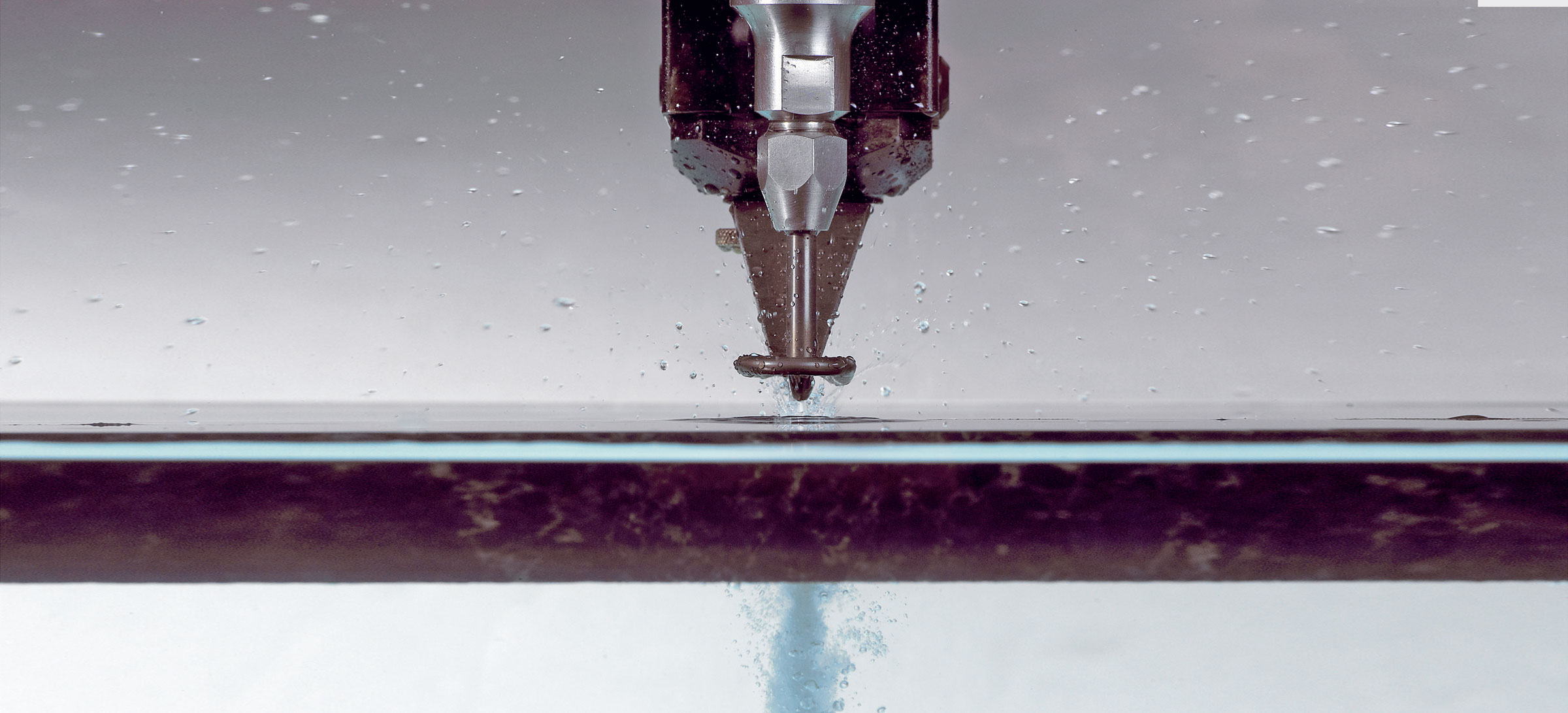

Advantages of waterjets Waterjets have a lower cost-per-piece for short runs compared to a punch or die press, due to the time and expensive to create the dies and punches. Creating the CAD drawing for a part is all that is needed when using waterjet cutting, with a punch press the drawing is only the… Read more »

Recent Comments